Wind Farm Siting, Installation and Operation

Before wind turbines can be installed, the most appropriate location or locations for them needs to be determined. The major objective of the siting process is to locate a wind turbine (or turbines) such that net revenue is maximized while minimizing such things as noise, environmental and visual impacts, and overall cost of energy. The scope of this process can have a very wide range, which could include everything from wind prospecting for suitable turbine sites over a wide geographical area to considering the placement of a single wind turbine on a site or of multiple wind turbines in a wind farm (this is generally called micrositing).

The decision of which areas to consider for siting wind farms and where to place wind turbines within a project is only one aspect of the development process which includes acquiring land rights, applying for permits, obtaining power purchase agreements, financing and public support, procuring turbines, and installation of the wind turbine or wind farm.

The siting of a single turbine or a large-scale wind system for utility interconnection can be broken down into five major stages:

1. Identification of geographic areas needing further study. Areas with high average wind speeds within the region of interest are identified using a wind resource atlas and any other available wind data. The characteristics of turbine types or designs under consideration are used to establish the minimum useful wind speed for each type.

2. Selection of candidate sites. Potential windy sites within the region are identified where the installation of one or more wind turbines appears to be practical from engineering and public acceptance standpoints. If the nature of the terrain in the candidate region is such that there is significant variation within it, then a detailed analysis is required to identify the best areas. At this stage, topographical considerations, ecological observations, and computer modeling may be used to evaluate the wind resource. Geologic, social, and cultural issues are also considered.

3. Preliminary evaluation of candidate sites. In this phase, each potential candidate site is ranked according to its economic potential, and the most viable sites are examined for any environmental impact, public acceptance, safety, and operational problems that would adversely affect their suitability as a wind turbine site. Once the best candidate sites are selected, a preliminary measurement program may be required.

4. Final site evaluation. For the best remaining candidate sites, a more comprehensive wind resource measurement may be required. At this point, the measurements should include wind shear and turbulence in addition to wind speed and prevailing wind directions.

5. Micrositing. Once a site is chosen, or possibly as part of the final site evaluation, the exact locations of the turbines and their energy production need to be determined. This may be able to be done with computer programs that can model the wind field and the various aerodynamic interactions between turbines that affect energy capture. The more complex the terrain, and the less the available data from nearby sites, the less accurate these models are. A site in complex terrain may require detailed measurements at numerous locations to determine the local wind field for micrositing decisions.

The evaluation of problems that might adversely affect a site’s suitability should include:

An estimation of the wind resource at potential project sites is at the heart of the siting process. As the siting process proceeds, knowledge of the wind resource in finer and finer detail is required. Initially, windy areas will need to be identified. For micrositing and the final evaluation of the economics of a project, as much detail as possible of the spatial variability of the wind resource across the site and the temporal variation over longer time scales is desired.

There are a number of possible approaches to determining the wind resource at candidate sites. Each of these has advantages and disadvantages and, thus, might be used at different stages of the siting process, depending on the information needed. These methods include (1) ecological methods, (2) the use of wind atlas data, (3) computer modeling, (4) mesoscale weather modeling, (5) statistical methods, and (6) long-term site-specific data collection.

Installation and Operation Issues

The installation of a wind power project is a complex process involving a number of steps and legal and technical issues. The process starts with securing legal rights and permit approvals. Once permits are obtained, the site needs to be prepared and the turbine transported to the site and erected. Only after the turbine is connected to the grid and commissioned does regular operation commence. At this point the owner is responsible for oversight of the turbine, safe operation, and maintenance. The project owner might be an individual or company, a utility, a local government, or a developer.

Predevelopment Work and Permitting

The first steps in the development process include securing legal rights to land (if the land is not already owned by the project owner) and access to power lines, starting to line up power purchase agreements (if the power is not to be used on-site), and obtaining permits. It may also include finding investors. Most of these legal and financial aspects of the development process are beyond the scope of this text, but the permitting process involves significant engineering issues and is addressed here.

The permitting process varies greatly from country to country, state to state, and even from town to town. It is intended to ensure that land is used appropriately, and that operation of the installed wind turbine or wind farm will be safe and environmentally benign. Generally, permits that must be obtained may include those related to: building construction, noise emission, land use, grid connection, environmental issues (birds, soil erosion, water quality, waste disposal, and wetland issues), public safety, occupational safety, and/or valuable cultural or archaeological sites. In the permit approval process the technical certification of the turbine may also be important. Wind power professionals in many countries have published information on issues to be considered in the permitting process. For example, more information on the permitting process in the United States can be found in Permitting of Wind Energy Facilities, A Handbook and in Wind Energy Siting Handbook.

Site Preparation

Once permits have been obtained, the site needs to be prepared for turbine installation and operation. Roads may need to be built; the site needs to be cleared for delivery, assembly, and erection of turbines; power lines need to be installed and foundations need to be built. The extent and difficulty of the site preparation will depend on the site location, proximity to power lines, and the turbine design and site terrain. Turbine foundation design needs to be site and turbine specific. Expected turbine loading, tower design, and soil properties (sand, bedrock, etc.) will affect the type and size of foundation needed. Road design will also depend heavily on the size and weight of the loads to be transported, the terrain, local weather conditions, soil properties, and any environmental restrictions. Obviously, rugged terrain can make all aspects of site preparation difficult and costly.

Turbine Transportation

The next significant hurdle may be transportation of the wind turbines to the site. Smaller turbines can often be packed in containers for easy transport over roads. Larger turbines must be transported in subsections and assembled at the site. In remote locations, difficult access may limit the feasible turbine size or design or may require expensive transportation methods such as helicopters or special purpose vehicles.

Turbine Assembly and Erection

Once at the site, the turbine must be assembled and erected. Issues related to assembly and erection need to be considered during the design phase to minimize installation costs. Ease of erection depends on the turbine size and weight, the availability of an appropriately sized crane, the turbine design, and site access. Small to medium-sized turbines can usually be assembled on site with a crane. Some can even be assembled on the ground and the whole tower and turbine placed on the foundation with a crane. Where site access is difficult or cranes are not available, such as in developing countries, it may be advantageous to use a turbine with a tilt-up tower. The complete turbine and tower are assembled on the ground and hydraulic pistons or winches are used to raise the tower about a hinge. This erection method can make maintenance easy, as the turbine can be lowered to the ground for easy access.

The erection of large wind turbines can present a significant technical challenge. The tower sections, blades, and the nacelle can each be very heavy and large. For example, the tower, nacelle, and blade weights of one 3 MW turbine are 156, 88, and 6.6 metric tonnes respectively. Very large cranes are often needed. Turbines have also been designed with telescoping towers for easier tower erection, or with lifting devices integral to the tower. The tower then acts not only as the support for the turbine, but also as the crane for placement of the tower top on the tower.

Grid Connection

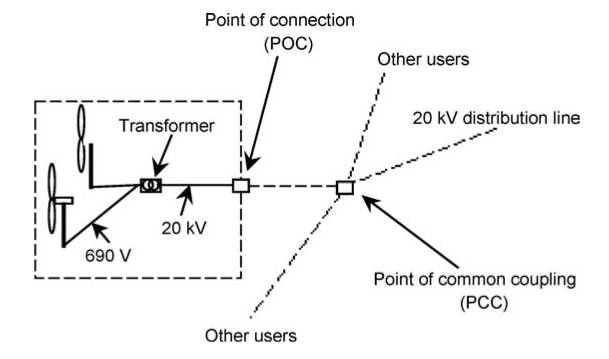

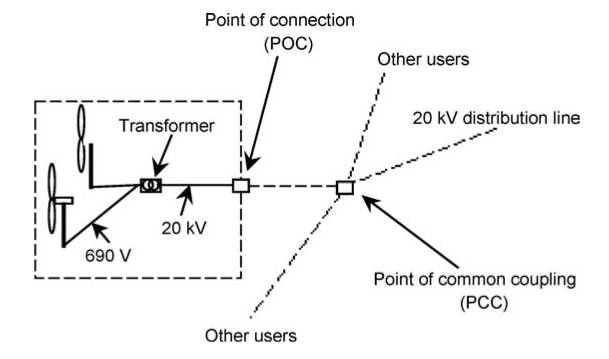

The turbine–grid connection consists of electrical conductors, transformers, and switchgear to enable connection and disconnection. All of this equipment must be thermally rated to handle the expected current and the electrical conductors must be sized large enough to minimize voltage drops between the turbine and the point of connection (POC) to the electrical grid. The POC is a commonly used term to denote the grid connection at the wind turbine owner’s property boundary. Another frequently used term is the point of common coupling, PCC. The PCC is the closest point in the grid system at which other users are connected to the grid. Details of the turbine–grid connection are presented in Section 9.5. Once the turbine is installed and connected to the grid, it is ready for operation.

Commissioning

Wind turbines need to be ‘commissioned’ before the turbine owner takes control of the turbine operation. Commissioning consists of (1) appropriate tests to ensure correct turbine operation and (2) maintenance and operation training for the turbine owner or operator. The extent of the commissioning process depends on the technical complexity of the turbine and the degree to which the design has been proven in previous installations. For mature turbine designs, commissioning consists of tests of the lubrication, electrical, and braking systems, operator training, confirmation of the power curve, and tests of turbine operation and control in a variety of wind speeds. Commissioning of (one-of-a-kind) research or prototype turbines includes numerous tests of the various subsystems while the turbine is standing still (lubrication and electrical systems, pitch mechanisms, yaw drives, brakes, etc.) before any tests with the operating turbine are performed.

Turbine Operation

Successful operation of a turbine or wind farm requires (1) information systems to monitor turbine performance, (2) understanding of factors that reduce turbine performance, and (3) measures to maximize turbine productivity.

Automatic turbine operation requires a system for oversight in order to provide operating information to the turbine owner and maintenance personnel. Many individual turbines and turbines in wind farms have the capability to communicate with remote oversight systems via phone connections. Remote oversight (SCADA) systems receive data from individual turbines and display it on computer screens for system operators. These data can be used to evaluate turbine energy capture and availability (the percentage of time that a wind turbine is available for power production).

The availability of wind turbines with mature designs is typically between 94% and 97% but may be below 90%. Reduced availability is caused by scheduled and unscheduled maintenance and repair periods, power system outages, and control system faults. For example, the inability of control systems to properly follow rapid changes in wind conditions, imbalance due to blade icing, or momentary high component temperatures can cause the controller to stop the turbine. The controller usually clears these fault conditions and operation is resumed. Repeated tripping usually causes the controller to take the turbine offline until a technician can determine the cause of anomalous sensor readings. This results in decreased turbine availability.

Wind turbine manufacturers provide power curves representing turbine power output as a function of wind speed. A number of factors may reduce the energy capture of a turbine or wind farm from that expected, based on the published power curve and the wind resource at the site. These include reduced availability, poor aerodynamic performance due to soiled blades and blade ice, lower power due to yaw error, control actions in response to wind conditions, and interactions between turbines in wind farms. Soiled blades have been observed to degrade aerodynamic performance by as much as 10–15%. Airfoils that are sensitive to dirt accumulation require either frequent cleaning or replacement with airfoils whose performance is less susceptible to degradation by the accumulation of dirt and insects. Blade ice accumulation can, similarly, degrade aerodynamic performance. Energy capture is also reduced when the wind direction changes. Controllers on some upwind turbine designs might wait until the magnitude of the average yaw error is above a predetermined value before adjusting the turbine orientation, resulting in periods of operation at high yaw errors. This results in lower energy capture. Turbulent winds can also cause a number of types of trips. For example, in turbulent winds, sudden high yaw errors might cause the system to shut down and restart, also reducing energy capture. In high winds, gusts can cause the turbine to shut down for protection when the mean wind speed is still well within the turbine operating range. These problems may reduce energy capture by as much as 15% of projected values. Operators should not only be prepared to minimize these problems, but should also anticipate them in their financing and planning evaluations.

Maintenance and Repair

Wind turbine components require regular maintenance and inspection to make sure that lubrication oil is clean, seals are functioning, and that components subject to normal wear processes are replaced. Problem conditions identified by oversight systems may require that the turbine be taken out of operation for repairs.

The decision of which areas to consider for siting wind farms and where to place wind turbines within a project is only one aspect of the development process which includes acquiring land rights, applying for permits, obtaining power purchase agreements, financing and public support, procuring turbines, and installation of the wind turbine or wind farm.

The siting of a single turbine or a large-scale wind system for utility interconnection can be broken down into five major stages:

1. Identification of geographic areas needing further study. Areas with high average wind speeds within the region of interest are identified using a wind resource atlas and any other available wind data. The characteristics of turbine types or designs under consideration are used to establish the minimum useful wind speed for each type.

2. Selection of candidate sites. Potential windy sites within the region are identified where the installation of one or more wind turbines appears to be practical from engineering and public acceptance standpoints. If the nature of the terrain in the candidate region is such that there is significant variation within it, then a detailed analysis is required to identify the best areas. At this stage, topographical considerations, ecological observations, and computer modeling may be used to evaluate the wind resource. Geologic, social, and cultural issues are also considered.

3. Preliminary evaluation of candidate sites. In this phase, each potential candidate site is ranked according to its economic potential, and the most viable sites are examined for any environmental impact, public acceptance, safety, and operational problems that would adversely affect their suitability as a wind turbine site. Once the best candidate sites are selected, a preliminary measurement program may be required.

4. Final site evaluation. For the best remaining candidate sites, a more comprehensive wind resource measurement may be required. At this point, the measurements should include wind shear and turbulence in addition to wind speed and prevailing wind directions.

5. Micrositing. Once a site is chosen, or possibly as part of the final site evaluation, the exact locations of the turbines and their energy production need to be determined. This may be able to be done with computer programs that can model the wind field and the various aerodynamic interactions between turbines that affect energy capture. The more complex the terrain, and the less the available data from nearby sites, the less accurate these models are. A site in complex terrain may require detailed measurements at numerous locations to determine the local wind field for micrositing decisions.

The evaluation of problems that might adversely affect a site’s suitability should include:

- Economic issues: Such as cost of access rights, energy production, wake losses, local taxes, substation costs.

- Topographical issues: Such as road access and the slope of the terrain at potential turbine sites.

- Legal issues: Such as ownership of the land, zoning issues and rights of adjacent land owners (for example, to the wind resource), and existing environmental contamination at the site.

- Permitting issues: Such as the number of permits needed, previous rulings of permitting agencies, permitting restrictions, and time frames for completion of permitting procedures.

- Geological issues: Related to the foundation design, ground resistance for lightning protection, and the potential for erosion.

- Environmental issues: Such as the presence of environmentally sensitive areas, bird flyways, and the presence of endangered species.

- Public acceptance issues: Such as visual and noise impacts, distance from residences, public safety, the presence of culturally, historically, or archaeologically important areas, competing land uses, and interference with microwave links and other communication.

- Safety issues: Related to proximity to populated areas or hiking trails.

- Interconnection issues: Such as the proximity of power lines and the voltage and current handling capacities of those power lines.

An estimation of the wind resource at potential project sites is at the heart of the siting process. As the siting process proceeds, knowledge of the wind resource in finer and finer detail is required. Initially, windy areas will need to be identified. For micrositing and the final evaluation of the economics of a project, as much detail as possible of the spatial variability of the wind resource across the site and the temporal variation over longer time scales is desired.

There are a number of possible approaches to determining the wind resource at candidate sites. Each of these has advantages and disadvantages and, thus, might be used at different stages of the siting process, depending on the information needed. These methods include (1) ecological methods, (2) the use of wind atlas data, (3) computer modeling, (4) mesoscale weather modeling, (5) statistical methods, and (6) long-term site-specific data collection.

Installation and Operation Issues

The installation of a wind power project is a complex process involving a number of steps and legal and technical issues. The process starts with securing legal rights and permit approvals. Once permits are obtained, the site needs to be prepared and the turbine transported to the site and erected. Only after the turbine is connected to the grid and commissioned does regular operation commence. At this point the owner is responsible for oversight of the turbine, safe operation, and maintenance. The project owner might be an individual or company, a utility, a local government, or a developer.

Predevelopment Work and Permitting

The first steps in the development process include securing legal rights to land (if the land is not already owned by the project owner) and access to power lines, starting to line up power purchase agreements (if the power is not to be used on-site), and obtaining permits. It may also include finding investors. Most of these legal and financial aspects of the development process are beyond the scope of this text, but the permitting process involves significant engineering issues and is addressed here.

The permitting process varies greatly from country to country, state to state, and even from town to town. It is intended to ensure that land is used appropriately, and that operation of the installed wind turbine or wind farm will be safe and environmentally benign. Generally, permits that must be obtained may include those related to: building construction, noise emission, land use, grid connection, environmental issues (birds, soil erosion, water quality, waste disposal, and wetland issues), public safety, occupational safety, and/or valuable cultural or archaeological sites. In the permit approval process the technical certification of the turbine may also be important. Wind power professionals in many countries have published information on issues to be considered in the permitting process. For example, more information on the permitting process in the United States can be found in Permitting of Wind Energy Facilities, A Handbook and in Wind Energy Siting Handbook.

Site Preparation

Once permits have been obtained, the site needs to be prepared for turbine installation and operation. Roads may need to be built; the site needs to be cleared for delivery, assembly, and erection of turbines; power lines need to be installed and foundations need to be built. The extent and difficulty of the site preparation will depend on the site location, proximity to power lines, and the turbine design and site terrain. Turbine foundation design needs to be site and turbine specific. Expected turbine loading, tower design, and soil properties (sand, bedrock, etc.) will affect the type and size of foundation needed. Road design will also depend heavily on the size and weight of the loads to be transported, the terrain, local weather conditions, soil properties, and any environmental restrictions. Obviously, rugged terrain can make all aspects of site preparation difficult and costly.

Turbine Transportation

The next significant hurdle may be transportation of the wind turbines to the site. Smaller turbines can often be packed in containers for easy transport over roads. Larger turbines must be transported in subsections and assembled at the site. In remote locations, difficult access may limit the feasible turbine size or design or may require expensive transportation methods such as helicopters or special purpose vehicles.

Turbine Assembly and Erection

Once at the site, the turbine must be assembled and erected. Issues related to assembly and erection need to be considered during the design phase to minimize installation costs. Ease of erection depends on the turbine size and weight, the availability of an appropriately sized crane, the turbine design, and site access. Small to medium-sized turbines can usually be assembled on site with a crane. Some can even be assembled on the ground and the whole tower and turbine placed on the foundation with a crane. Where site access is difficult or cranes are not available, such as in developing countries, it may be advantageous to use a turbine with a tilt-up tower. The complete turbine and tower are assembled on the ground and hydraulic pistons or winches are used to raise the tower about a hinge. This erection method can make maintenance easy, as the turbine can be lowered to the ground for easy access.

The erection of large wind turbines can present a significant technical challenge. The tower sections, blades, and the nacelle can each be very heavy and large. For example, the tower, nacelle, and blade weights of one 3 MW turbine are 156, 88, and 6.6 metric tonnes respectively. Very large cranes are often needed. Turbines have also been designed with telescoping towers for easier tower erection, or with lifting devices integral to the tower. The tower then acts not only as the support for the turbine, but also as the crane for placement of the tower top on the tower.

Grid Connection

The turbine–grid connection consists of electrical conductors, transformers, and switchgear to enable connection and disconnection. All of this equipment must be thermally rated to handle the expected current and the electrical conductors must be sized large enough to minimize voltage drops between the turbine and the point of connection (POC) to the electrical grid. The POC is a commonly used term to denote the grid connection at the wind turbine owner’s property boundary. Another frequently used term is the point of common coupling, PCC. The PCC is the closest point in the grid system at which other users are connected to the grid. Details of the turbine–grid connection are presented in Section 9.5. Once the turbine is installed and connected to the grid, it is ready for operation.

Commissioning

Wind turbines need to be ‘commissioned’ before the turbine owner takes control of the turbine operation. Commissioning consists of (1) appropriate tests to ensure correct turbine operation and (2) maintenance and operation training for the turbine owner or operator. The extent of the commissioning process depends on the technical complexity of the turbine and the degree to which the design has been proven in previous installations. For mature turbine designs, commissioning consists of tests of the lubrication, electrical, and braking systems, operator training, confirmation of the power curve, and tests of turbine operation and control in a variety of wind speeds. Commissioning of (one-of-a-kind) research or prototype turbines includes numerous tests of the various subsystems while the turbine is standing still (lubrication and electrical systems, pitch mechanisms, yaw drives, brakes, etc.) before any tests with the operating turbine are performed.

Successful operation of a turbine or wind farm requires (1) information systems to monitor turbine performance, (2) understanding of factors that reduce turbine performance, and (3) measures to maximize turbine productivity.

Automatic turbine operation requires a system for oversight in order to provide operating information to the turbine owner and maintenance personnel. Many individual turbines and turbines in wind farms have the capability to communicate with remote oversight systems via phone connections. Remote oversight (SCADA) systems receive data from individual turbines and display it on computer screens for system operators. These data can be used to evaluate turbine energy capture and availability (the percentage of time that a wind turbine is available for power production).

The availability of wind turbines with mature designs is typically between 94% and 97% but may be below 90%. Reduced availability is caused by scheduled and unscheduled maintenance and repair periods, power system outages, and control system faults. For example, the inability of control systems to properly follow rapid changes in wind conditions, imbalance due to blade icing, or momentary high component temperatures can cause the controller to stop the turbine. The controller usually clears these fault conditions and operation is resumed. Repeated tripping usually causes the controller to take the turbine offline until a technician can determine the cause of anomalous sensor readings. This results in decreased turbine availability.

Wind turbine manufacturers provide power curves representing turbine power output as a function of wind speed. A number of factors may reduce the energy capture of a turbine or wind farm from that expected, based on the published power curve and the wind resource at the site. These include reduced availability, poor aerodynamic performance due to soiled blades and blade ice, lower power due to yaw error, control actions in response to wind conditions, and interactions between turbines in wind farms. Soiled blades have been observed to degrade aerodynamic performance by as much as 10–15%. Airfoils that are sensitive to dirt accumulation require either frequent cleaning or replacement with airfoils whose performance is less susceptible to degradation by the accumulation of dirt and insects. Blade ice accumulation can, similarly, degrade aerodynamic performance. Energy capture is also reduced when the wind direction changes. Controllers on some upwind turbine designs might wait until the magnitude of the average yaw error is above a predetermined value before adjusting the turbine orientation, resulting in periods of operation at high yaw errors. This results in lower energy capture. Turbulent winds can also cause a number of types of trips. For example, in turbulent winds, sudden high yaw errors might cause the system to shut down and restart, also reducing energy capture. In high winds, gusts can cause the turbine to shut down for protection when the mean wind speed is still well within the turbine operating range. These problems may reduce energy capture by as much as 15% of projected values. Operators should not only be prepared to minimize these problems, but should also anticipate them in their financing and planning evaluations.

Maintenance and Repair

Wind turbine components require regular maintenance and inspection to make sure that lubrication oil is clean, seals are functioning, and that components subject to normal wear processes are replaced. Problem conditions identified by oversight systems may require that the turbine be taken out of operation for repairs.

Post a Comment:

You may also like:

Featured Articles

What is a Capacity Factor?

Wind turbines convert the kinetic energy in moving air into rotational energy, which in turn is converted to ...

Wind turbines convert the kinetic energy in moving air into rotational energy, which in turn is converted to ...

Wind turbines convert the kinetic energy in moving air into rotational energy, which in turn is converted to ...

Wind turbines convert the kinetic energy in moving air into rotational energy, which in turn is converted to ...Basics of Wind Farms

Throughout history, wind has been used to move grain mills or push the vessels that sailed the seas. However, it was not ...

Throughout history, wind has been used to move grain mills or push the vessels that sailed the seas. However, it was not ...

Throughout history, wind has been used to move grain mills or push the vessels that sailed the seas. However, it was not ...

Throughout history, wind has been used to move grain mills or push the vessels that sailed the seas. However, it was not ...Basics of Wind Energy Production

In the United States, most wind energy is commercially generated for delivery and sale on the grid. Wind projects vary in ...

In the United States, most wind energy is commercially generated for delivery and sale on the grid. Wind projects vary in ...

In the United States, most wind energy is commercially generated for delivery and sale on the grid. Wind projects vary in ...

In the United States, most wind energy is commercially generated for delivery and sale on the grid. Wind projects vary in ...What is Wind Energy?

Wind is moving air. We can use the energy in wind to do work. Early Egyptians used the wind to sail ships on the Nile River. ...

Wind is moving air. We can use the energy in wind to do work. Early Egyptians used the wind to sail ships on the Nile River. ...

Wind is moving air. We can use the energy in wind to do work. Early Egyptians used the wind to sail ships on the Nile River. ...

Wind is moving air. We can use the energy in wind to do work. Early Egyptians used the wind to sail ships on the Nile River. ...Wind Farm Siting, Installation and ...

Before wind turbines can be installed, the most appropriate location or locations for them needs to be determined. The ...

Before wind turbines can be installed, the most appropriate location or locations for them needs to be determined. The ...

Before wind turbines can be installed, the most appropriate location or locations for them needs to be determined. The ...

Before wind turbines can be installed, the most appropriate location or locations for them needs to be determined. The ...