Home » News & Events » Wind Energy Cost Trends

Wind Energy Cost Trends

Though the cost of wind energy has declined significantly since the 1980s, policy measures are currently required to ensure rapid deployment in most regions of the world. In some areas with good wind resources, however, the cost of wind energy is competitive with current energy market prices. Moreover, continued technology advances in on- and offshore wind energy are expected, supporting further cost reductions. The degree to which wind energy is utilized globally and regionally will depend largely on the economic performance of wind energy compared to alternative power sources.

Factors that affect the cost of wind energy

The levelized cost of energy from on- and offshore wind power plants is affected by five primary factors: annual energy production, investment costs, O&M costs, financing costs and the assumed economic life of the plant. Available support policies can also influence the cost (and price) of wind energy, as well as the cost of other electricity supply options, but these factors are not addressed here.

The nature of the wind resource, which varies geographically and temporally, largely determines the annual energy production from a prospective wind power plant, and is among the most important economic factors. Precise micro-siting of wind power plants and even individual turbines is critical for maximizing energy production. The trend towards turbines with larger rotor diameters and taller towers has led to increases in annual energy production per unit of installed capacity, and has also allowed wind power plants in lower-resource areas to become more economically competitive. Larger wind power plants, meanwhile, have led to consideration of array effects whereby the production of downwind turbines is affected by those turbines located upwind. Offshore power plants will, generally, be exposed to better wind resources than will onshore plants.

Wind power plants are capital intensive and, over their lifetime, the initial investment cost ranges from 75 to 80% of total expenditure, with O&M costs contributing the balance. The investment cost includes the cost of the turbines (turbines, transportation to site, and installation), grid connection (cables, sub-station, connection), civil works (foundations, roads, buildings), and other costs (engineering, licensing, permitting, environmental assessments and monitoring equipment). Table 1 shows a rough breakdown of the investment cost components for modern wind power plants. Turbine costs comprise more than 70% of total investment costs for onshore wind power plants. The remaining investment costs are highly site-specific. Offshore wind power plants are dominated by these other costs, with the turbines often contributing less than 50% of the total. Site-dependent characteristics such as water depth and distance to shore significantly affect grid connection, civil works and other costs. Offshore turbine foundations and internal electric grids are also considerably costlier than those for onshore power plants.

The O&M costs of wind power plants include fixed costs such as land leases, insurance, taxes, management, and forecasting services, as well as variable costs related to the maintenance and repair of turbines, including spare parts. O&M comprises approximately 20% of total wind power plant expenditure over a plant’s lifetime, with roughly 50% of total O&M costs associated directly with maintenance, repair and spare parts. O&M costs for offshore wind energy are higher than for onshore due to the less mature state of technology as well as the challenges and costs of accessing offshore turbines, especially in harsh weather conditions).

Financing arrangements, including the cost of debt and equity and the proportional use of each, can also influence the cost of wind energy, as can the expected operating life of the wind power plant. For example, ownership and financing structures have evolved in the USA that minimize the cost of capital while taking advantage of available incentives. Other research has found that the predictability of the policy measures supporting wind energy can have a sizable impact on financing costs, and therefore the ultimate cost of wind energy. Because offshore wind power plants are still relatively new, with greater performance risk, higher financing costs are experienced than for onshore plants, and larger fi rms tend to dominate offshore wind energy development and ownership.

Trends of Investment costs

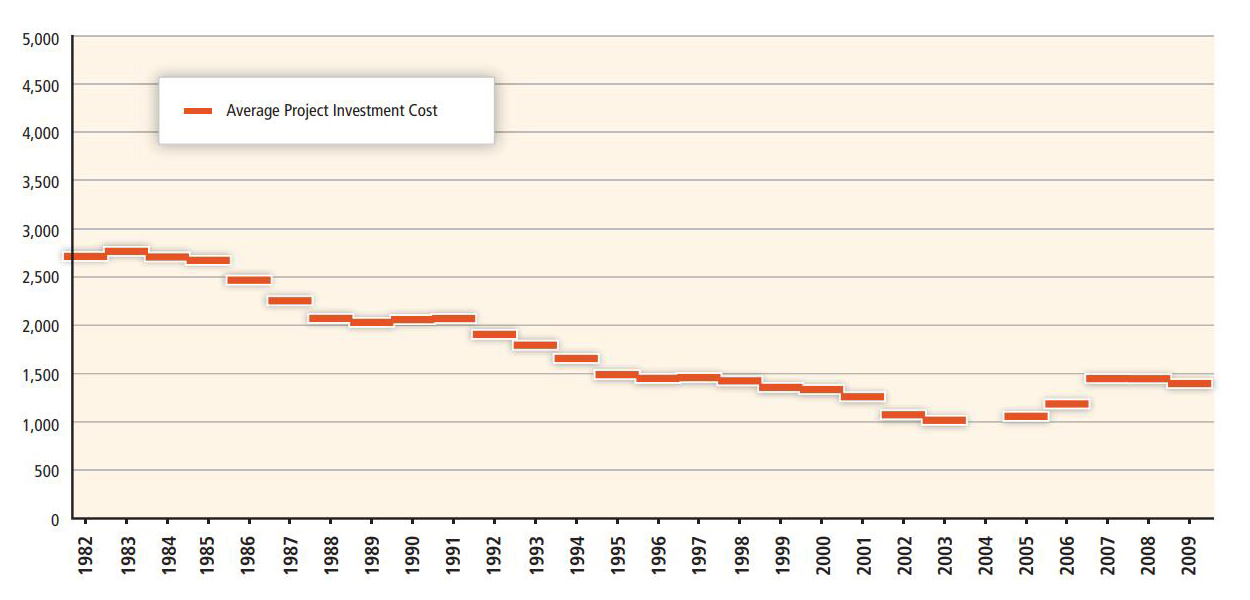

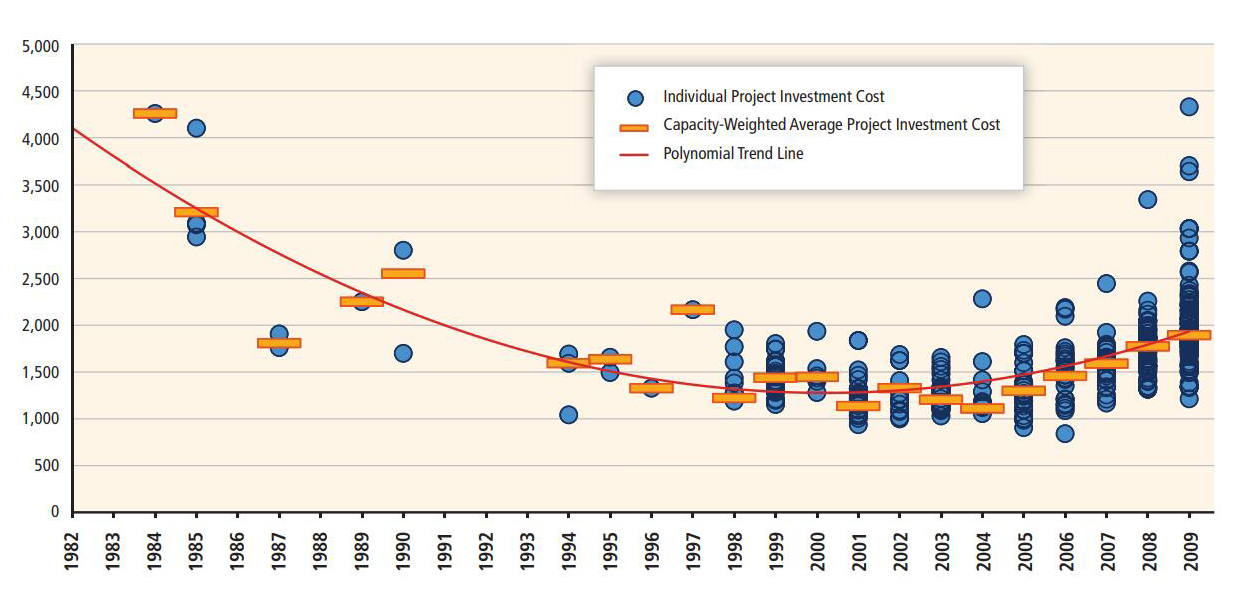

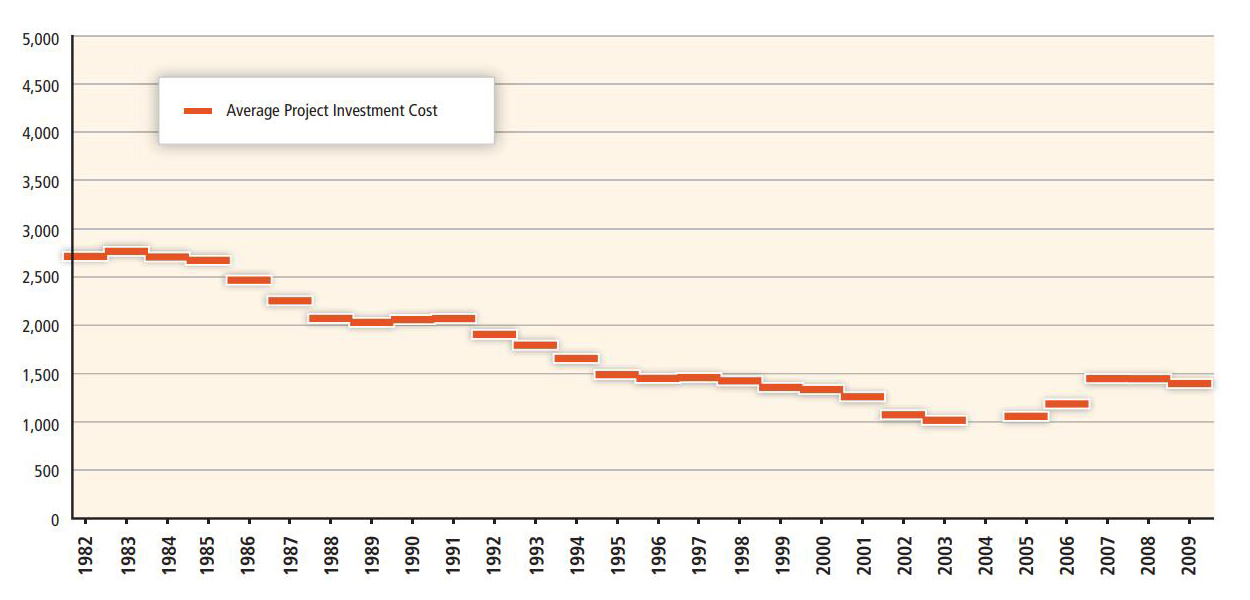

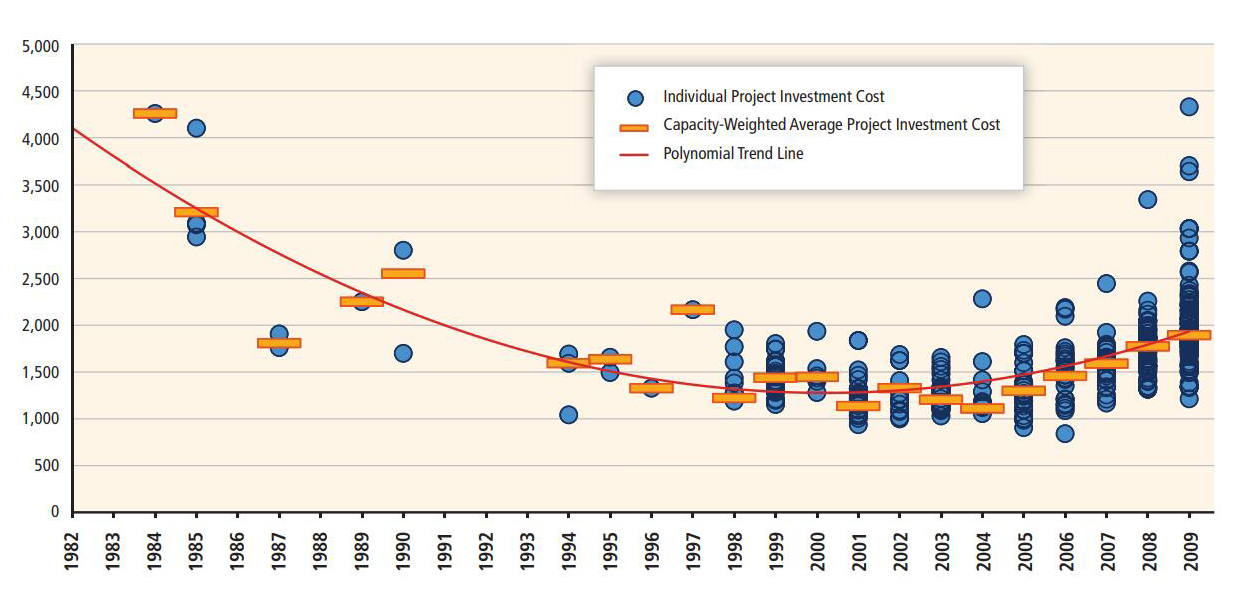

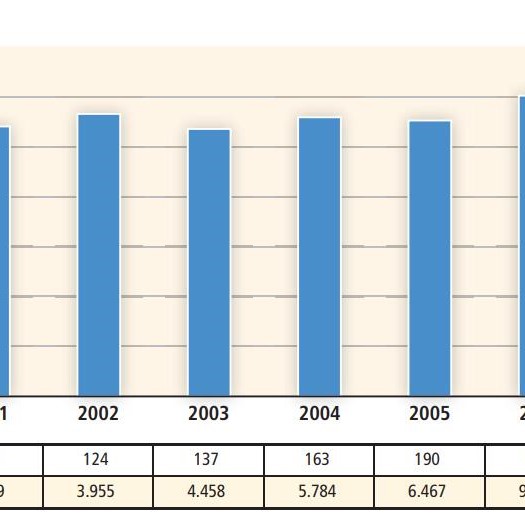

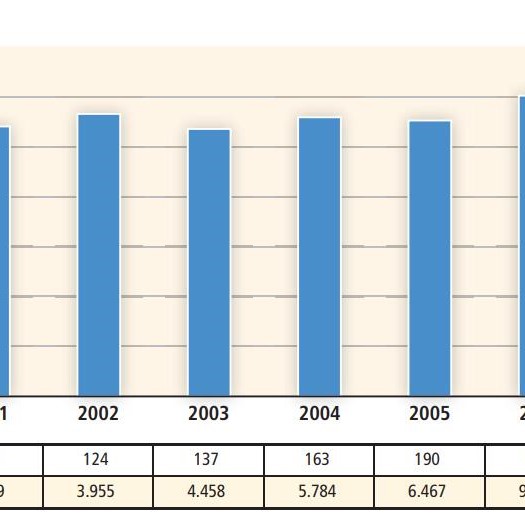

From the beginnings of commercial wind energy deployment to roughly 2004, the average investment costs of onshore wind power plants dropped, while turbine size grew significantly. With each generation Investment costs presented here and later (as well as all resulting levelized cost of energy estimates) generally include the cost of the turbines (turbines, transportation to site and installation), grid connection (cables, sub-station, connection, but not more general transmission expansion costs), civil works (foundations, roads, buildings), and other costs (engineering, licensing, permitting, environmental assessments, and monitoring equipment). Whether the cost of connecting to the grid is included varies by data source, and is sometimes unclear; costs associated with strengthening the ‘backbone’ transmission system are generally excluded. of wind turbine technology during this period, design improvements and turbine scaling led to decreased investment costs. Historical investment cost data from Denmark and the USA demonstrate this trend (Figure 1).

Figure 1

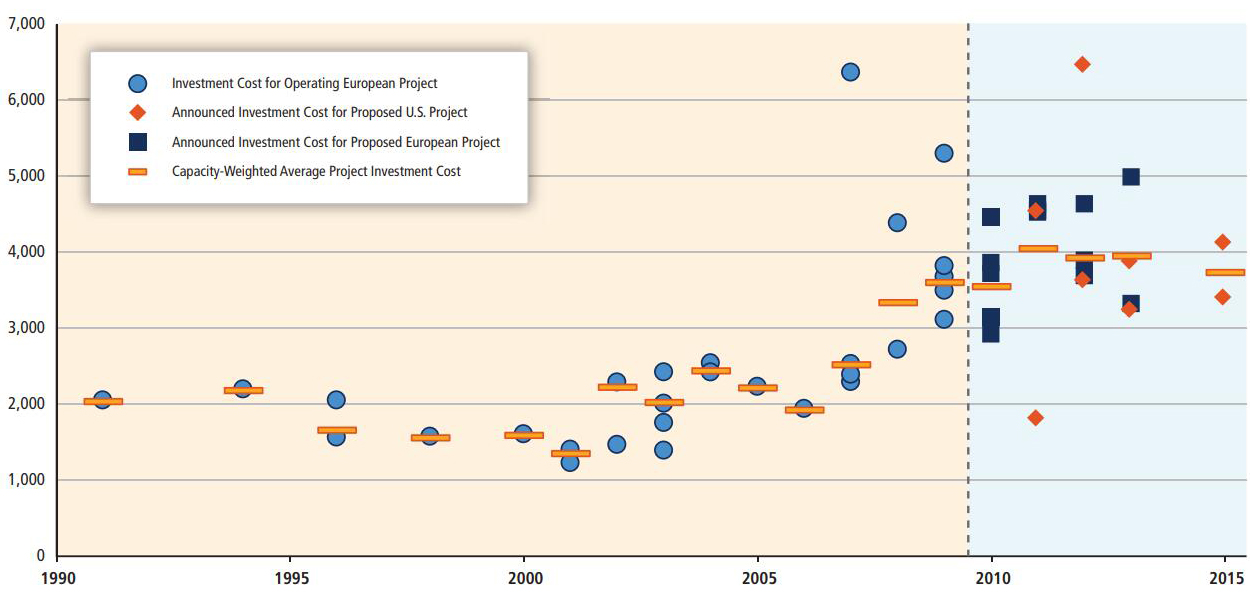

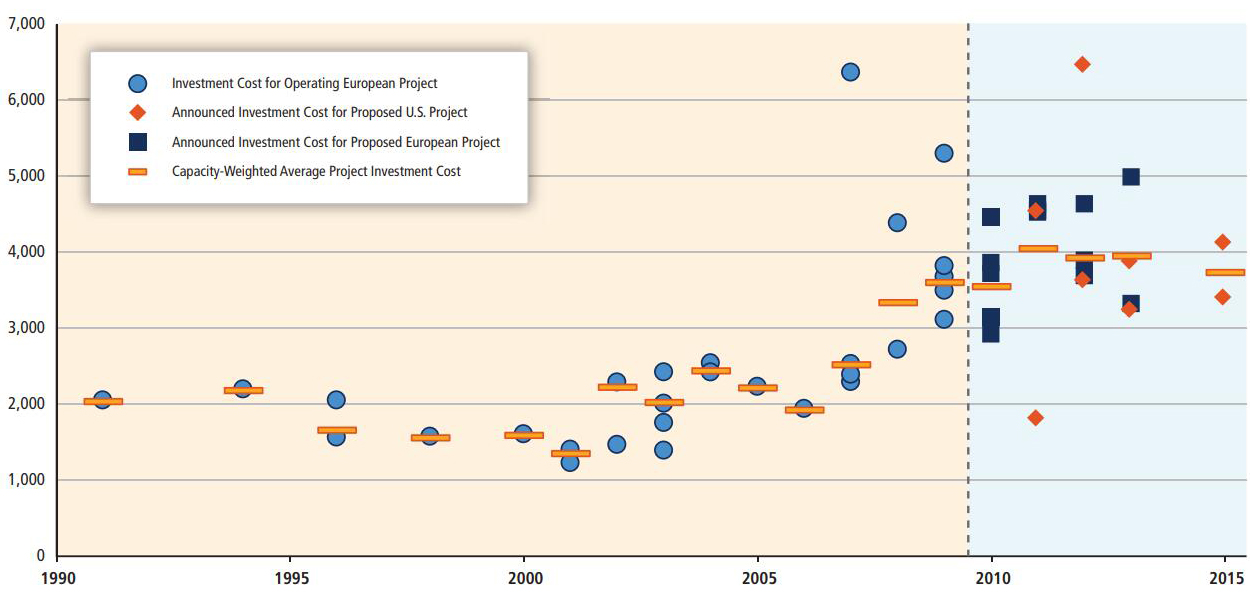

There is far less experience with offshore wind power plants, and the investment costs of offshore plants are highly site-specific. Nonetheless, the investment costs of offshore plants have historically been 50 to more than 100% higher than for onshore plants. Moreover, offshore wind power plants built to date have generally been constructed in relatively shallow water and relatively close to shore; higher costs would be experienced for deeper water and more distant facilities. Figure 2 presents investment cost data for operating and announced offshore wind power plants. Offshore costs have been influenced by some of the same factors that caused rising onshore costs from 2004 through 2009 (as well as several unique factors), leading to a doubling of the average investment cost of offshore plants from 2004 through 2009.

Trends of Operation and maintenance

Trends of Operation and maintenance

Modern turbines that meet IEC standards are designed for a 20-year life, and plant lifetimes may exceed 20 years if O&M costs remain at an acceptable level. Few wind power plants were constructed 20 or more years ago, however, and there is therefore limited experience in plant operations over this entire time period. Moreover, those plants that have reached or exceeded their 20-year lifetime tend to have turbines that are much smaller and less sophisticated than their modern counterparts. Early turbines were also designed using more conservative criteria, though they followed less stringent standards than today’s designs. As a result, early plants only offer limited guidance for estimating O&M costs for more recent turbine designs.

In general, O&M costs during the first couple of years of a wind power plant’s life are covered, in part, by manufacturer warranties that are included in the turbine purchase, resulting in lower ongoing costs than in subsequent years. Newer turbine models also tend to have lower initial O&M costs than older models, with maintenance costs increasing as turbines age. Offshore wind power plants have historically incurred higher O&M costs than onshore plants.

Trends of Energy production

The performance of wind power plants is highly site-specific, and is primarily governed by the characteristics of the local wind regime, which varies geographically and temporally. Wind power plant performance is also impacted by wind turbine design optimization, performance, and availability, however, and by the effectiveness of O&M procedures. Improved resource assessment and siting methodologies developed in the 1970s and 1980s played a major role in improved wind power plant productivity. Advances in wind energy technology, including taller towers and larger rotors, have also contributed to increased energy capture.

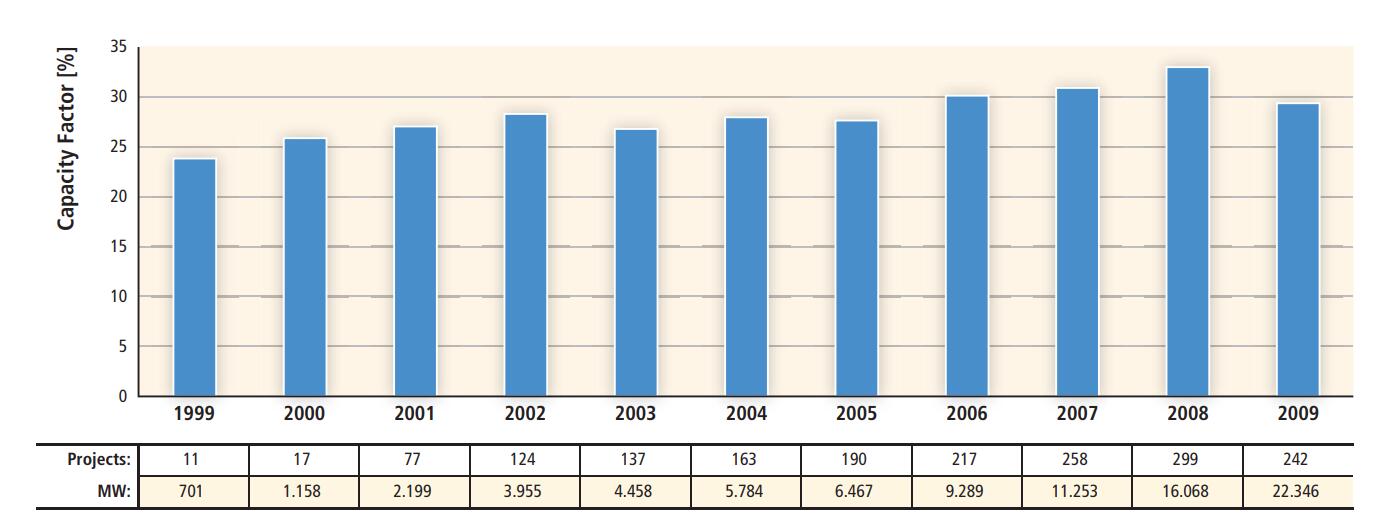

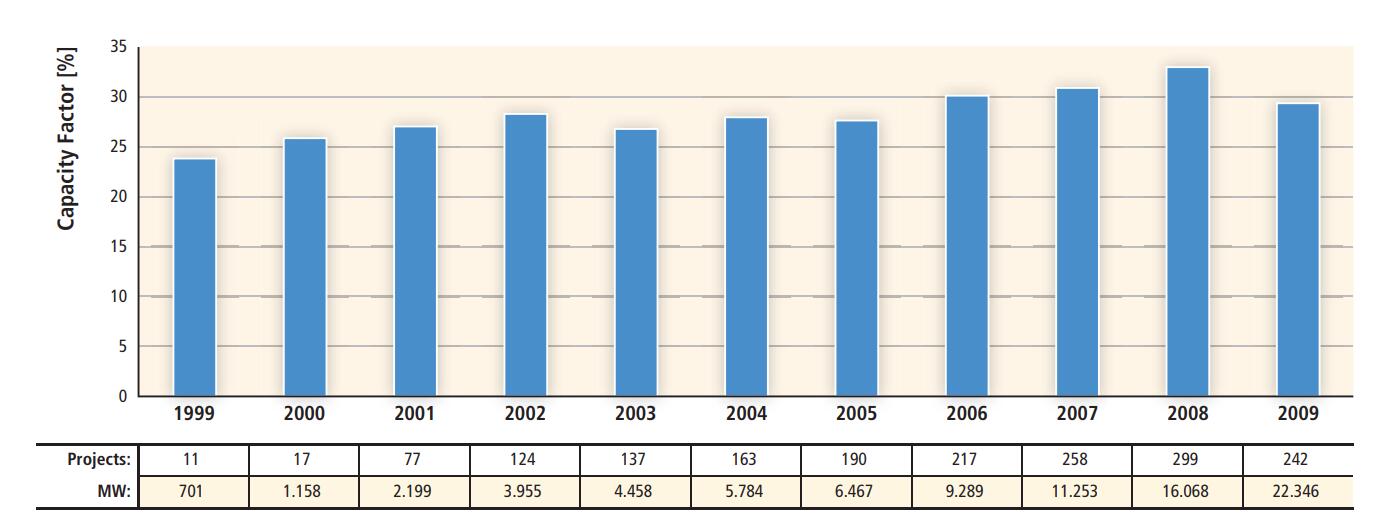

Though plant-level capacity factors vary widely, data on average fleetwide capacity factors for a large sample of onshore wind power plants in the USA show a trend towards higher average capacity factors over time, as wind power plants built more recently have higher average capacity factors than those built earlier. Higher hub heights and larger rotor sizes are primarily responsible for these improvements, as the more recent wind power plants built in this time period and included in Figure 3 were, on average, sited in relatively lower-quality wind resource regimes.

Figure 3

Using a different metric for wind power plant performance, annual energy production per square meter of swept rotor area (kWh/m2) for a given wind resource site, improvements of 2 to 3% per year over the last 15 years have been documented.

Potential for further reductions in the cost of wind energy

The wind energy industry has developed over a period of 30 years. Though the dramatic cost reductions seen in past decades will not continue indefinitely, the potential for further reductions remains given the many potential areas of technological advances. These potential spans both on- and offshore wind energy technologies; given the relatively less mature state of offshore wind energy, however, greater cost reductions can be expected in that segment. Two approaches are commonly used to forecast the future cost of wind energy, often in concert with some degree of expert judgement:

Factors that affect the cost of wind energy

The levelized cost of energy from on- and offshore wind power plants is affected by five primary factors: annual energy production, investment costs, O&M costs, financing costs and the assumed economic life of the plant. Available support policies can also influence the cost (and price) of wind energy, as well as the cost of other electricity supply options, but these factors are not addressed here.

The nature of the wind resource, which varies geographically and temporally, largely determines the annual energy production from a prospective wind power plant, and is among the most important economic factors. Precise micro-siting of wind power plants and even individual turbines is critical for maximizing energy production. The trend towards turbines with larger rotor diameters and taller towers has led to increases in annual energy production per unit of installed capacity, and has also allowed wind power plants in lower-resource areas to become more economically competitive. Larger wind power plants, meanwhile, have led to consideration of array effects whereby the production of downwind turbines is affected by those turbines located upwind. Offshore power plants will, generally, be exposed to better wind resources than will onshore plants.

Wind power plants are capital intensive and, over their lifetime, the initial investment cost ranges from 75 to 80% of total expenditure, with O&M costs contributing the balance. The investment cost includes the cost of the turbines (turbines, transportation to site, and installation), grid connection (cables, sub-station, connection), civil works (foundations, roads, buildings), and other costs (engineering, licensing, permitting, environmental assessments and monitoring equipment). Table 1 shows a rough breakdown of the investment cost components for modern wind power plants. Turbine costs comprise more than 70% of total investment costs for onshore wind power plants. The remaining investment costs are highly site-specific. Offshore wind power plants are dominated by these other costs, with the turbines often contributing less than 50% of the total. Site-dependent characteristics such as water depth and distance to shore significantly affect grid connection, civil works and other costs. Offshore turbine foundations and internal electric grids are also considerably costlier than those for onshore power plants.

| Cost Component | Onshore (%) | Offshore (%) |

| Turbine | 71-76 | 37-49 |

| Grid connection | 10-12 | 21-23 |

| Civil works | 7-9 | 21-25 |

| Other investment costs | 5-8 | 9-15 |

Table 1: Investment cost distribution for on- and offshore wind power plants

Financing arrangements, including the cost of debt and equity and the proportional use of each, can also influence the cost of wind energy, as can the expected operating life of the wind power plant. For example, ownership and financing structures have evolved in the USA that minimize the cost of capital while taking advantage of available incentives. Other research has found that the predictability of the policy measures supporting wind energy can have a sizable impact on financing costs, and therefore the ultimate cost of wind energy. Because offshore wind power plants are still relatively new, with greater performance risk, higher financing costs are experienced than for onshore plants, and larger fi rms tend to dominate offshore wind energy development and ownership.

Trends of Investment costs

From the beginnings of commercial wind energy deployment to roughly 2004, the average investment costs of onshore wind power plants dropped, while turbine size grew significantly. With each generation Investment costs presented here and later (as well as all resulting levelized cost of energy estimates) generally include the cost of the turbines (turbines, transportation to site and installation), grid connection (cables, sub-station, connection, but not more general transmission expansion costs), civil works (foundations, roads, buildings), and other costs (engineering, licensing, permitting, environmental assessments, and monitoring equipment). Whether the cost of connecting to the grid is included varies by data source, and is sometimes unclear; costs associated with strengthening the ‘backbone’ transmission system are generally excluded. of wind turbine technology during this period, design improvements and turbine scaling led to decreased investment costs. Historical investment cost data from Denmark and the USA demonstrate this trend (Figure 1).

Figure 1

Figure 2

Modern turbines that meet IEC standards are designed for a 20-year life, and plant lifetimes may exceed 20 years if O&M costs remain at an acceptable level. Few wind power plants were constructed 20 or more years ago, however, and there is therefore limited experience in plant operations over this entire time period. Moreover, those plants that have reached or exceeded their 20-year lifetime tend to have turbines that are much smaller and less sophisticated than their modern counterparts. Early turbines were also designed using more conservative criteria, though they followed less stringent standards than today’s designs. As a result, early plants only offer limited guidance for estimating O&M costs for more recent turbine designs.

In general, O&M costs during the first couple of years of a wind power plant’s life are covered, in part, by manufacturer warranties that are included in the turbine purchase, resulting in lower ongoing costs than in subsequent years. Newer turbine models also tend to have lower initial O&M costs than older models, with maintenance costs increasing as turbines age. Offshore wind power plants have historically incurred higher O&M costs than onshore plants.

Trends of Energy production

The performance of wind power plants is highly site-specific, and is primarily governed by the characteristics of the local wind regime, which varies geographically and temporally. Wind power plant performance is also impacted by wind turbine design optimization, performance, and availability, however, and by the effectiveness of O&M procedures. Improved resource assessment and siting methodologies developed in the 1970s and 1980s played a major role in improved wind power plant productivity. Advances in wind energy technology, including taller towers and larger rotors, have also contributed to increased energy capture.

Though plant-level capacity factors vary widely, data on average fleetwide capacity factors for a large sample of onshore wind power plants in the USA show a trend towards higher average capacity factors over time, as wind power plants built more recently have higher average capacity factors than those built earlier. Higher hub heights and larger rotor sizes are primarily responsible for these improvements, as the more recent wind power plants built in this time period and included in Figure 3 were, on average, sited in relatively lower-quality wind resource regimes.

Figure 3

Using a different metric for wind power plant performance, annual energy production per square meter of swept rotor area (kWh/m2) for a given wind resource site, improvements of 2 to 3% per year over the last 15 years have been documented.

Potential for further reductions in the cost of wind energy

The wind energy industry has developed over a period of 30 years. Though the dramatic cost reductions seen in past decades will not continue indefinitely, the potential for further reductions remains given the many potential areas of technological advances. These potential spans both on- and offshore wind energy technologies; given the relatively less mature state of offshore wind energy, however, greater cost reductions can be expected in that segment. Two approaches are commonly used to forecast the future cost of wind energy, often in concert with some degree of expert judgement:

- Learning curve estimates that assume that future wind energy costs will follow a trajectory that is similar to an historical learning curve based on past costs.

- Engineering-based estimates of the specific cost reduction possibilities associated with new or improved wind energy technologies or manufacturing capabilities.

Post a Comment:

You may also like:

Featured Articles

Economic Impacts of Wind Industry

Any business development will have economic impacts on the local and regional economies, and wind energy projects are no ...

Any business development will have economic impacts on the local and regional economies, and wind energy projects are no ...

Any business development will have economic impacts on the local and regional economies, and wind energy projects are no ...

Any business development will have economic impacts on the local and regional economies, and wind energy projects are no ...Environmental Impacts of Wind Industry

In recent years, the growth of capacity to generate electricity from wind energy has been extremely rapid, To the ...

In recent years, the growth of capacity to generate electricity from wind energy has been extremely rapid, To the ...

In recent years, the growth of capacity to generate electricity from wind energy has been extremely rapid, To the ...

In recent years, the growth of capacity to generate electricity from wind energy has been extremely rapid, To the ...Challenges in Wind Industry

While wind power generation offers numerous benefits and advantages over conventional power generation, there are also some ...

While wind power generation offers numerous benefits and advantages over conventional power generation, there are also some ...

While wind power generation offers numerous benefits and advantages over conventional power generation, there are also some ...

While wind power generation offers numerous benefits and advantages over conventional power generation, there are also some ...Employment Impacts of Wind Industry

As with most construction and commercial development, wind energy industry create jobs. According to the 2016 Clean Jobs New ...

As with most construction and commercial development, wind energy industry create jobs. According to the 2016 Clean Jobs New ...

As with most construction and commercial development, wind energy industry create jobs. According to the 2016 Clean Jobs New ...

As with most construction and commercial development, wind energy industry create jobs. According to the 2016 Clean Jobs New ...Wind Energy Cost Trends

Though the cost of wind energy has declined significantly since the 1980s, policy measures are currently required to ensure ...

Though the cost of wind energy has declined significantly since the 1980s, policy measures are currently required to ensure ...

Though the cost of wind energy has declined significantly since the 1980s, policy measures are currently required to ensure ...

Though the cost of wind energy has declined significantly since the 1980s, policy measures are currently required to ensure ...