Home » Application » Application in Severe Climates

Application in Severe Climates

Operation in severe climates imposes special design considerations on wind turbines. Severe climates may include those with unusually high extreme winds, high moisture and humidity, very high or low temperatures, and lightning.

High temperatures and moisture in warm climates cause a number of problems. High temperatures can thin lubricants, degrade the operation of electronics, and may affect motion in mechanical systems that expand with the heat. Moisture and humidity can corrode metal and degrade the operation of electronics. Moisture problems may require the use of desiccants, dehumidifiers, and improved sealing systems. All of these problems can be solved with site-specific design details, but these should be anticipated before the system is installed in the field.

Operation in cold temperatures also raises unique design considerations. A number of wind turbines have been installed in cold weather regions of the globe, including Finland, northern Quebec, Alaska, and other cold regions of Europe and North America and in Antarctica. Experience has shown that cold weather locations can impose significant design and operating requirements on wind turbines because of sensor and turbine icing, material properties at low temperatures, permafrost, and snow.

Turbine icing is a significant problem in cold climates. Ice comes in two main forms: glaze ice and rime ice. Glaze ice is the result of rain freezing on cold surfaces and occurs close to 0 C. Glaze ice is usually transparent and forms sheets of ice over large surfaces. Rime ice results when supercooled moisture droplets in the air contact a cold surface. Rime ice accumulation occurs in temperatures colder than 0℃ Ice accumulation on aerodynamic surfaces degrades turbine performance and, on anemometers and wind vanes, results in either no information from these sensors or misleading information. Ice can also result in rotor imbalance, malfunctioning aerodynamic brakes, downed power lines, and a danger to personnel from falling ice. Attempts to deal with some of these problems have included special blade coatings (Teflon, black paint) to reduce ice build-up, heating systems, and electrical or pneumatic devices to dislodge accumulated ice.

Cold weather also affects material properties. Cold weather reduces the flexibility of rubber seals, causing leaks, reduces clearances, reduces fracture strength, and increases lubricating oil viscosity. Each of these can cause mechanical malfunctions or problems in everything from solenoids to gearboxes. Most turbines designed for cold weather operation include heaters on a number of critical parts to ensure correct operation. Materials also become more brittle in cold climates. Component strengths may need to be de-rated for cold climate operation or special materials may be required for the correct operation of components in cold weather or to ensure adequate fatigue life.

Wind turbine installation and operation may be affected by cold weather climate conditions. Wind turbine access may be severely limited by deep snows. This may result in longer down times for turbine problems, or delayed and expensive maintenance. In installation in permafrost, the turbine installation season may be limited to the winter when the permafrost is fully frozen and transportation is easier.

More information on wind turbine operation in cold weather may be found in the proceedings of the seven (so far) BOREAS conferences. These are conferences which have a particular focus on wind energy in cold climates. The conferences are held periodically in northern Europe. Many of the papers from these conferences are available on the Internet.

Finally, many regions have frequent occurrences of lightning. Lightning can damage blades and mechanical and electrical components as it travels to ground. Designing for lightning protection includes providing very low impedance electrical paths to ground that bypass important turbine components, protecting circuitry with voltage surge protectors, and designing a low impedance grounding system (IEC, 2002).

High temperatures and moisture in warm climates cause a number of problems. High temperatures can thin lubricants, degrade the operation of electronics, and may affect motion in mechanical systems that expand with the heat. Moisture and humidity can corrode metal and degrade the operation of electronics. Moisture problems may require the use of desiccants, dehumidifiers, and improved sealing systems. All of these problems can be solved with site-specific design details, but these should be anticipated before the system is installed in the field.

Operation in cold temperatures also raises unique design considerations. A number of wind turbines have been installed in cold weather regions of the globe, including Finland, northern Quebec, Alaska, and other cold regions of Europe and North America and in Antarctica. Experience has shown that cold weather locations can impose significant design and operating requirements on wind turbines because of sensor and turbine icing, material properties at low temperatures, permafrost, and snow.

Turbine icing is a significant problem in cold climates. Ice comes in two main forms: glaze ice and rime ice. Glaze ice is the result of rain freezing on cold surfaces and occurs close to 0 C. Glaze ice is usually transparent and forms sheets of ice over large surfaces. Rime ice results when supercooled moisture droplets in the air contact a cold surface. Rime ice accumulation occurs in temperatures colder than 0℃ Ice accumulation on aerodynamic surfaces degrades turbine performance and, on anemometers and wind vanes, results in either no information from these sensors or misleading information. Ice can also result in rotor imbalance, malfunctioning aerodynamic brakes, downed power lines, and a danger to personnel from falling ice. Attempts to deal with some of these problems have included special blade coatings (Teflon, black paint) to reduce ice build-up, heating systems, and electrical or pneumatic devices to dislodge accumulated ice.

Cold weather also affects material properties. Cold weather reduces the flexibility of rubber seals, causing leaks, reduces clearances, reduces fracture strength, and increases lubricating oil viscosity. Each of these can cause mechanical malfunctions or problems in everything from solenoids to gearboxes. Most turbines designed for cold weather operation include heaters on a number of critical parts to ensure correct operation. Materials also become more brittle in cold climates. Component strengths may need to be de-rated for cold climate operation or special materials may be required for the correct operation of components in cold weather or to ensure adequate fatigue life.

Wind turbine installation and operation may be affected by cold weather climate conditions. Wind turbine access may be severely limited by deep snows. This may result in longer down times for turbine problems, or delayed and expensive maintenance. In installation in permafrost, the turbine installation season may be limited to the winter when the permafrost is fully frozen and transportation is easier.

More information on wind turbine operation in cold weather may be found in the proceedings of the seven (so far) BOREAS conferences. These are conferences which have a particular focus on wind energy in cold climates. The conferences are held periodically in northern Europe. Many of the papers from these conferences are available on the Internet.

Finally, many regions have frequent occurrences of lightning. Lightning can damage blades and mechanical and electrical components as it travels to ground. Designing for lightning protection includes providing very low impedance electrical paths to ground that bypass important turbine components, protecting circuitry with voltage surge protectors, and designing a low impedance grounding system (IEC, 2002).

Post a Comment:

You may also like:

Featured Articles

Applications for Small Wind Turbines

Small-scale wind energy is a small but rapidly growing segment of the RE industry in the US. Like other renewable sources, in its ...

Small-scale wind energy is a small but rapidly growing segment of the RE industry in the US. Like other renewable sources, in its ...

Small-scale wind energy is a small but rapidly growing segment of the RE industry in the US. Like other renewable sources, in its ...

Small-scale wind energy is a small but rapidly growing segment of the RE industry in the US. Like other renewable sources, in its ...Wind Turbine for Onshore Application

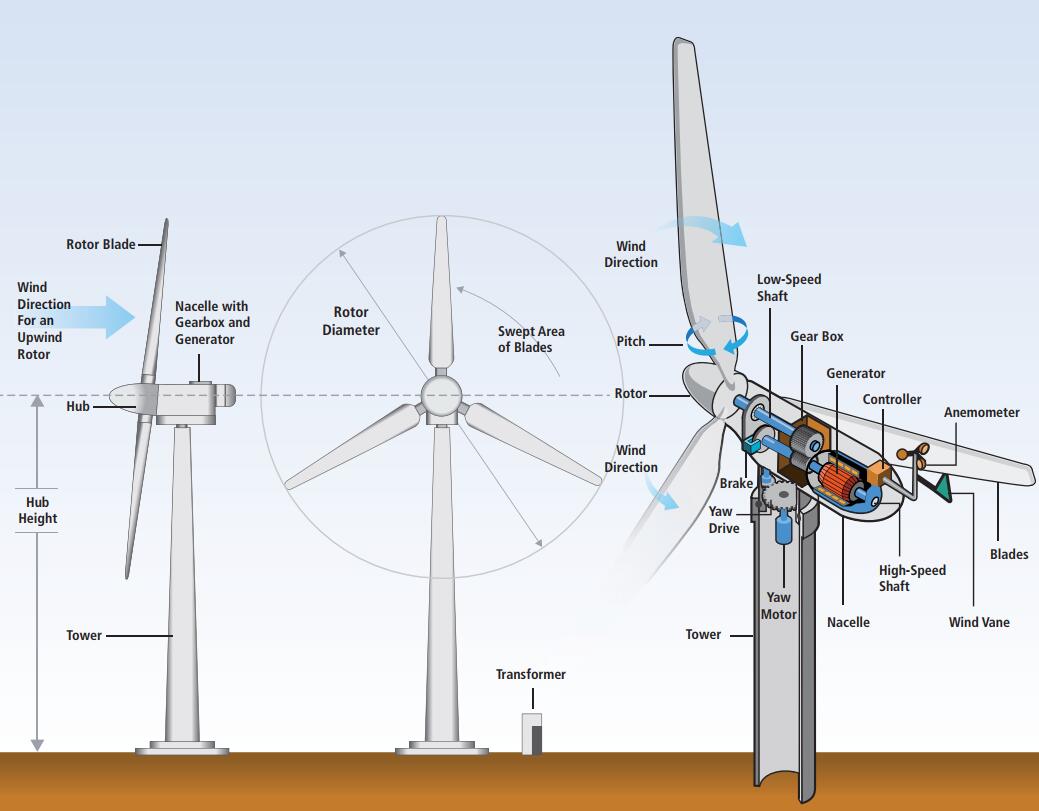

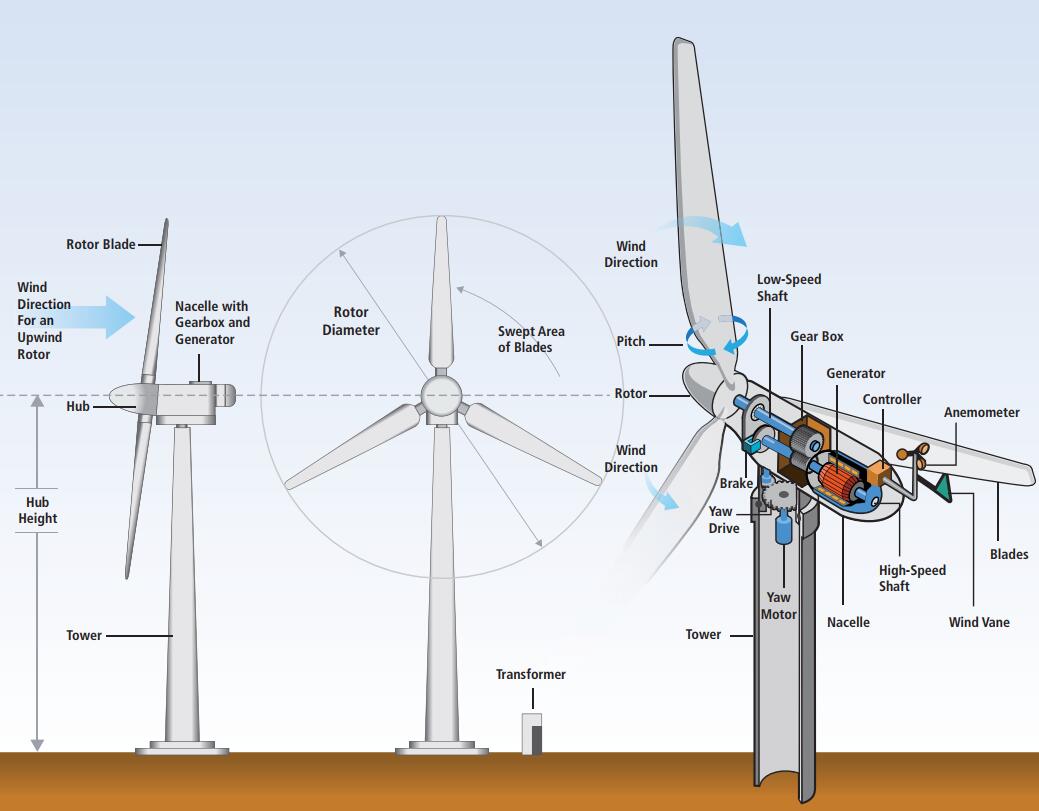

Modern, commercial grid-connected wind turbines have evolved from small, simple machines to large,highly ...

Modern, commercial grid-connected wind turbines have evolved from small, simple machines to large,highly ...

Modern, commercial grid-connected wind turbines have evolved from small, simple machines to large,highly ...

Modern, commercial grid-connected wind turbines have evolved from small, simple machines to large,highly ...History of Wind Energy Applications

Wind is used to produce electricity by converting the kinetic energy of air in motion into electricity. In modern wind ...

Wind is used to produce electricity by converting the kinetic energy of air in motion into electricity. In modern wind ...

Wind is used to produce electricity by converting the kinetic energy of air in motion into electricity. In modern wind ...

Wind is used to produce electricity by converting the kinetic energy of air in motion into electricity. In modern wind ...Application in Energy Storage

With the development of science and technology, energy storage is one of the most effective ways to solve the problem of ...

With the development of science and technology, energy storage is one of the most effective ways to solve the problem of ...

With the development of science and technology, energy storage is one of the most effective ways to solve the problem of ...

With the development of science and technology, energy storage is one of the most effective ways to solve the problem of ...Application in Severe Climates

Operation in severe climates imposes special design considerations on wind turbines. Severe climates may include those with ...

Operation in severe climates imposes special design considerations on wind turbines. Severe climates may include those with ...

Operation in severe climates imposes special design considerations on wind turbines. Severe climates may include those with ...

Operation in severe climates imposes special design considerations on wind turbines. Severe climates may include those with ...